Description

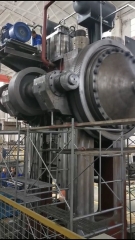

FP/MP Series Hot Die Forging Press

Introduction:

As a series of products imported and produced with advanced technology from the world - hot die forging press. It is extremely important in manufacturing industries such as automobiles, tractors, internal combustion engines, aviation, mining machinery, ships, petroleum machinery, and hardware tools. It can be used for forging large batches of black and non-ferrous metal forgings and precision forgings (and the products forged through it have higher precision, greatly improved material utilization and productivity). Hot die forging presses not only achieve automated production, but also have low technical requirements for workers' operations. They also have advantages such as low noise and vibration. Therefore, hot die forging presses are widely used in modern forging production and are also one of the indispensable high-precision forging equipment in modern forging production.

Regarding the purpose of hot die forging press: Hot die forging press can be widely used in the processing and manufacturing of automobiles, tractors, internal combustion engines, aviation, mining machinery, ships, petroleum machinery, and hardware tools, and is also one of the indispensable high-precision forging equipment in modern forging production.

Characterstic:

(1) The hot die forging press adopts a design of upper and lower top materials, with less inclination of the mold cavity and low consumption of raw materials, which can greatly save forging materials.

(2) The hot forging press can effectively improve production efficiency.

(3) The hot die forging press has a fast stroke, which can greatly shorten the contact time between the forging material and the mold, and also improve the service life of the mold to a certain extent.

(4) The hot die forging press breaks the traditional short stroke specification and can increase the stroke of this machine, making it more suitable for various forging drawing and forming operations.

(5) Can complete fully automatic stamping operations.

(6) The hot forging press has high production efficiency, simple operation, and easy maintenance.

(7) The hot forging press can effectively reduce noise pollution and comply with environmental laws.

(8) Hot die forging press can effectively reduce production costs.

(9) The hot die forging press adopts American tonnage CNC display, which not only visually displays the actual forging process, but also has overload control and alarm functions.

Parameter:

Introduction:

As a series of products imported and produced with advanced technology from the world - hot die forging press. It is extremely important in manufacturing industries such as automobiles, tractors, internal combustion engines, aviation, mining machinery, ships, petroleum machinery, and hardware tools. It can be used for forging large batches of black and non-ferrous metal forgings and precision forgings (and the products forged through it have higher precision, greatly improved material utilization and productivity). Hot die forging presses not only achieve automated production, but also have low technical requirements for workers' operations. They also have advantages such as low noise and vibration. Therefore, hot die forging presses are widely used in modern forging production and are also one of the indispensable high-precision forging equipment in modern forging production.

Regarding the purpose of hot die forging press: Hot die forging press can be widely used in the processing and manufacturing of automobiles, tractors, internal combustion engines, aviation, mining machinery, ships, petroleum machinery, and hardware tools, and is also one of the indispensable high-precision forging equipment in modern forging production.

Characterstic:

(1) The hot die forging press adopts a design of upper and lower top materials, with less inclination of the mold cavity and low consumption of raw materials, which can greatly save forging materials.

(2) The hot forging press can effectively improve production efficiency.

(3) The hot die forging press has a fast stroke, which can greatly shorten the contact time between the forging material and the mold, and also improve the service life of the mold to a certain extent.

(4) The hot die forging press breaks the traditional short stroke specification and can increase the stroke of this machine, making it more suitable for various forging drawing and forming operations.

(5) Can complete fully automatic stamping operations.

(6) The hot forging press has high production efficiency, simple operation, and easy maintenance.

(7) The hot forging press can effectively reduce noise pollution and comply with environmental laws.

(8) Hot die forging press can effectively reduce production costs.

(9) The hot die forging press adopts American tonnage CNC display, which not only visually displays the actual forging process, but also has overload control and alarm functions.

Parameter:

| Model | Nominal force(Kn) | Slider stroke(mm) | Slider adjustment amount(mm) |

Min die height(mm) | Stroke number(t/min) | Slider bottom dimension (FRxLR)(mm) |

Worktable dimension (FRxLR)(mm) |

Motor(Kw) |

|

FP-400 |

4000 |

180 |

8 |

370 |

100 |

600✖600 |

850✖760 |

37 |

|

FP-630 |

6300 |

200 |

8 |

400 |

85 |

660✖790 |

1000✖880 |

55 |

|

FP-1000 |

10000 |

250 |

10 |

460 |

80 |

830✖950 |

1150✖1120 |

75 |

|

MP-1600 |

16000 |

280 |

14 |

675 |

75 |

1050✖1110 |

1300✖1220 |

110 |

|

MP-2500 |

25000 |

320 |

18 |

1000 |

70 |

1280✖1200 |

1600✖1300 |

160 |

|

MP-4000 |

40000 |

360 |

28 |

1100 |

55 |

1730✖1340 |

2060✖1490 |

250 |

|

MP-5000 |

50000 |

400 |

32 |

1200 |

45 |

1875✖1550 |

2250✖1570 |

280 |

|

MP-6300 |

63000 |

450 |

35 |

1370 |

35 |

1925✖1800 |

2350✖1840 |

355 |